What’s The Problem?

Millions of blades disposed annually create environmental and safety concerns.

Metal blades are non-degradable and accumulate in landfills.

Improper disposal risks injury, requiring proper containment.

Some blades, like ceramics, are non-recyclable, increasing waste.

Solutions include better recycling or extending blade life through redesign.

(RecycleNation) (selectsafety)

Research

Researched the Kiridashi, a traditional Japanese scribing blade known for simplicity and effectiveness.

The Kiridashi embodies the essence of a sustainable utility knife.

Created a hand-filed, heat-treated, and hand-sharpened Kiridashi from W-1 Tool steel.

This process provided foundational insights into sustainable and effective cutting tools.

Ideation

Transitioned to sketching and brainstorming various design ideas.

Focused on incorporating traditional box cutter blade mechanics.

Aimed to enhance blade longevity while maintaining effectiveness.

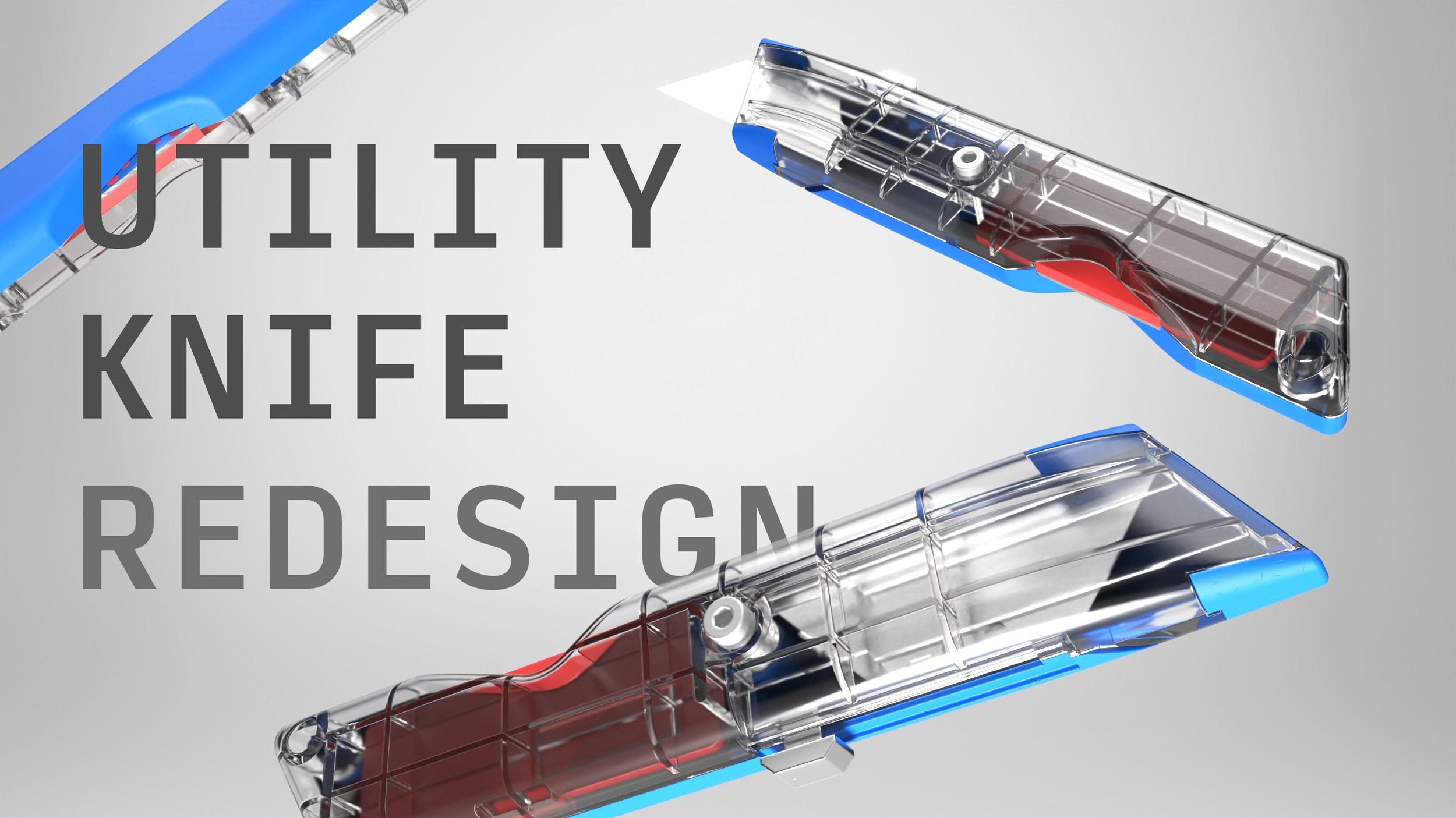

Modeling

Sketched ideas were translated into CAD models.

Models were manipulated and refined for further development.

Focused on visualizing spatial arrangement and mechanical functionality.

Prototype

3D printed prototypes were created to test CAD models.

Hands-on testing led to multiple small design changes and optimizations.

Iterative testing refined component fitment for functionality and user-friendliness.

Sustainability Focus

Features a built-in DMT Diamond Stone sharpener instead of disposable blade storage.

Allows users to sharpen and maintain a single blade continuously.

Reduces frequent blade replacements, minimizing waste and environmental impact.